Stegman Inspection Services provides mechanical testing to assure compliance to customer specification of raw materials. We evaluate strength, ductility, hardness, bends, and proof loading of materials.

Emailed Certified Test Reports with your requirement and/or your metallurgical trace data documented with each order.

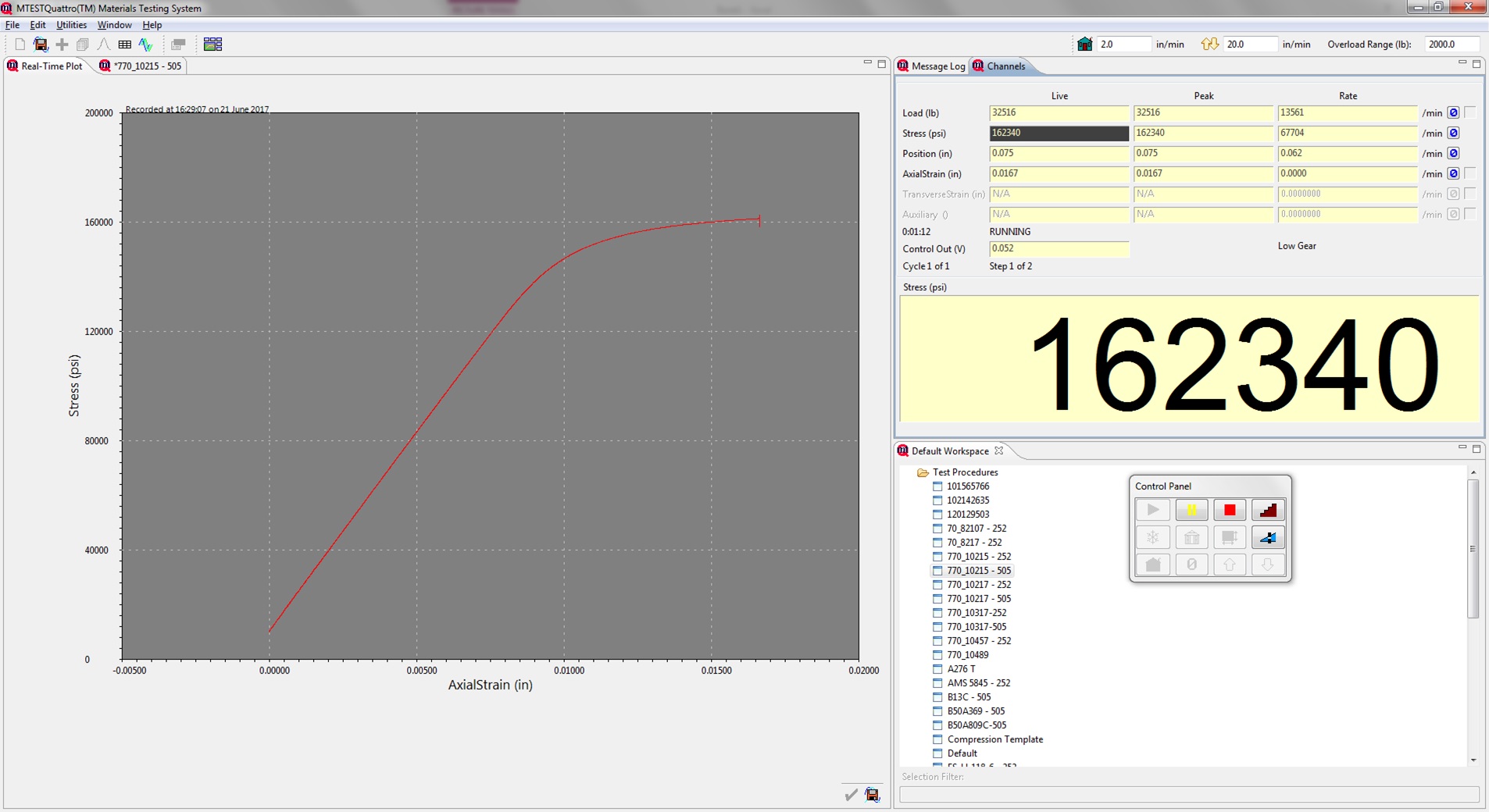

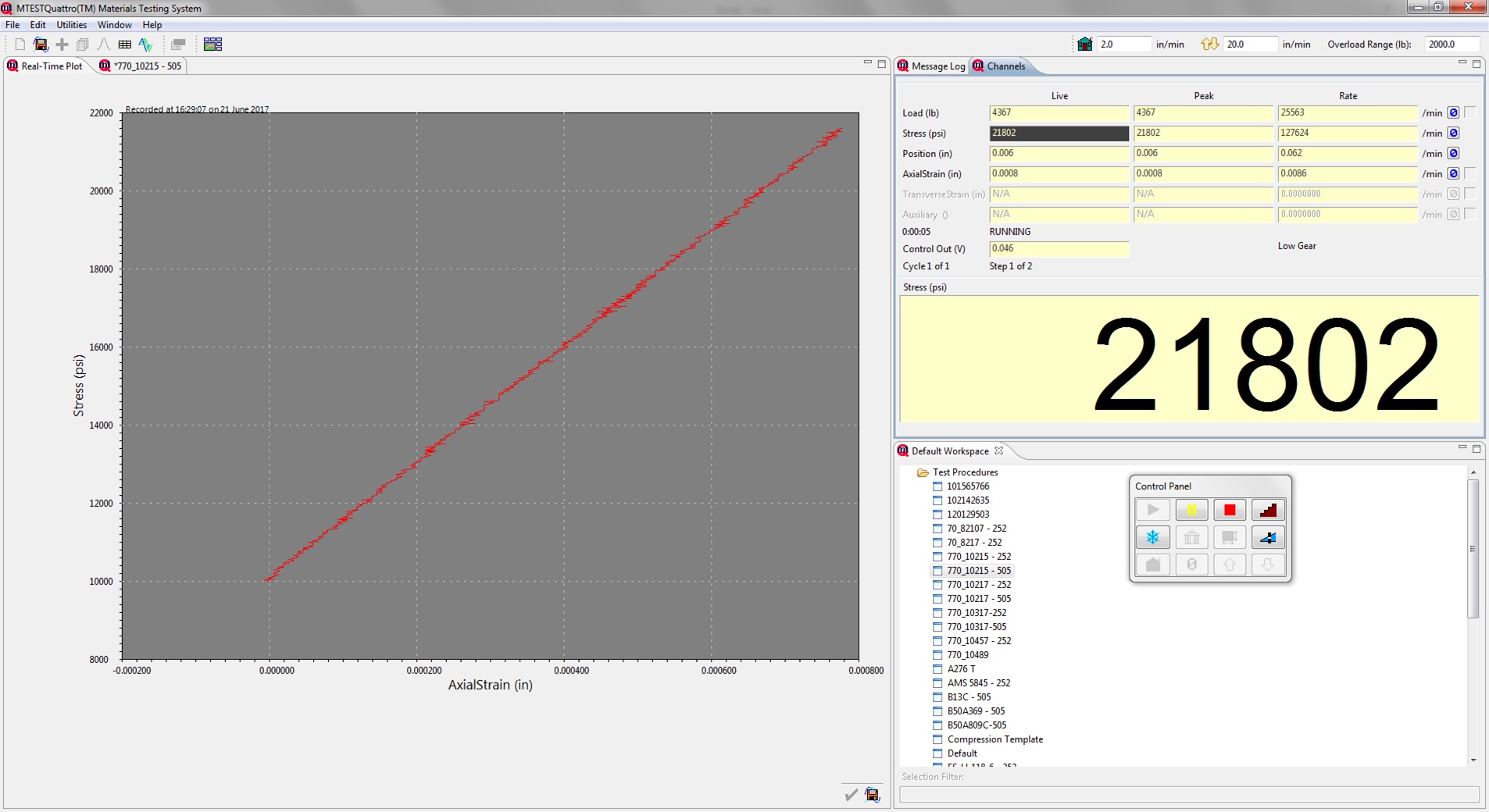

Tensile Testing

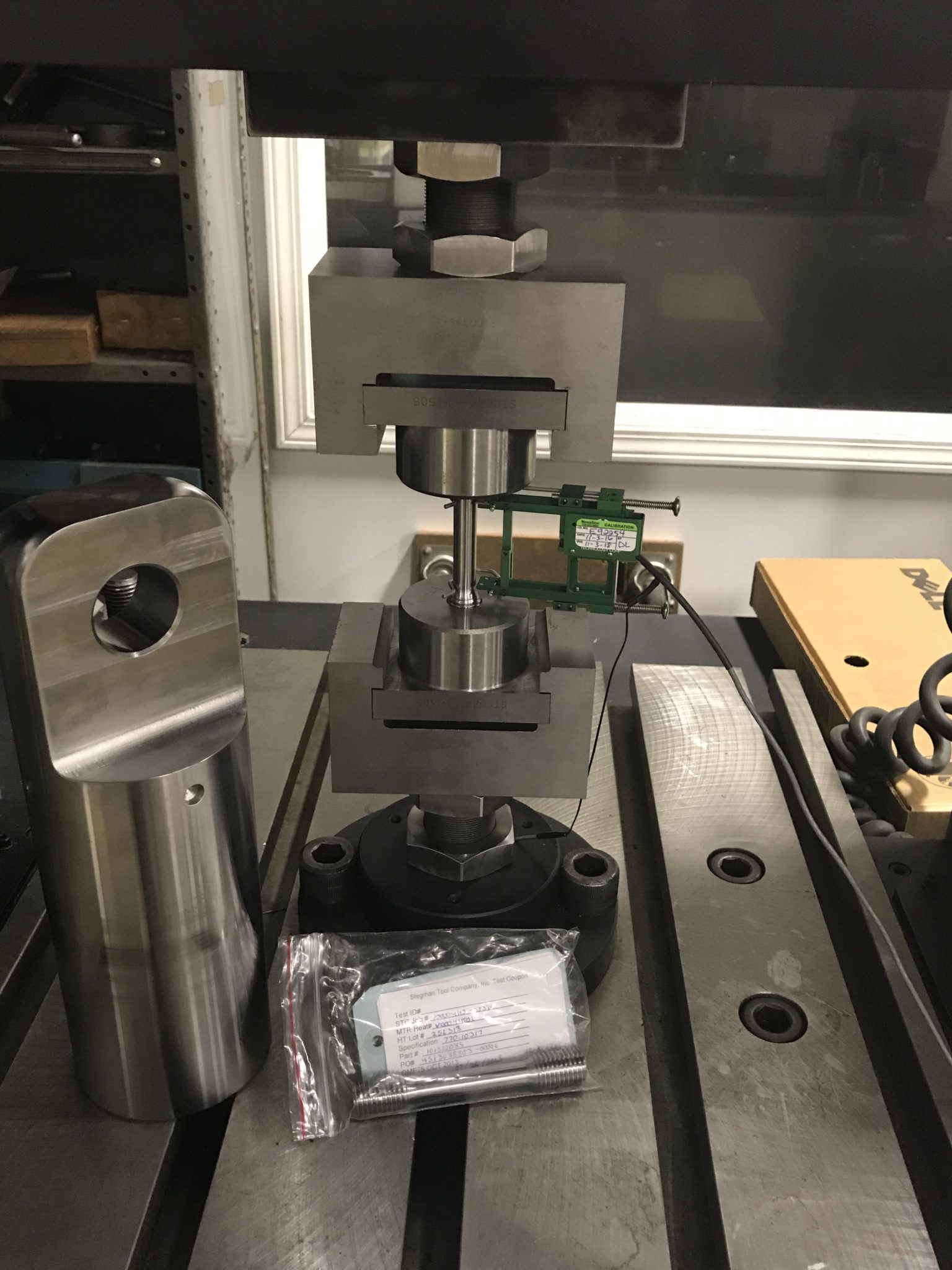

Stegman Inspection Services 110,000 lbf tensile tester provides a destructive mechanical test that defines the maximum energy the material can withstand before breaking. Our in-house machine shop will transform the raw material into a test specimen to provide the following results:

- Tensile Strength

- Yield Strength

- Elongation

- Reduction of Area

Tensile testing is available for any metallic material. Testing is performed per:

- ASTM E8 – Tension Testing of Metallic Materials

- ASTM A370 – Standard Test Methods and Definitions for Mechanical Testing of Steel Products

- ASTM B557 – Tension Testing Wrought and Cast Aluminum and Magnesium Alloy Products

- Customer Specific Process/Component Specifications

[ezcol_1half] [/ezcol_1half][ezcol_1half_end]

[/ezcol_1half][ezcol_1half_end] [/ezcol_1half_end]

[/ezcol_1half_end]

Proof Loading

A proof load test is used to define if a test sample can withstand a certain specified load at a certain specified time. The result of the test can show if the material has acceptable to no amount of deflection and/or elongation. Proof load can be performed on but not limited to:

- Bail Hooks and Lifting Devices

- Welded Structures

- Material Specimens “dog bones”

Proof Load Testing is performed per:

- ASTM A370-10 Mechanical Testing of Steel Products

- Customer Specific Process/Component Specifications

Compression Testing

A compression test determines behavior of materials under crushing loads. The specimen is compressed and deformation at various loads is recorded. Stegman Inspection services can test materials such as:

- Concrete

- Metals

- Plastic

- Ceramics

- Composites

- Springs

- Corrugated

- Cardboard

Compression Testing is performed per:

- ASTM E9 Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature

- ASTM C39 Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens

- ASTM D1621 Plastic Compression Testing

Bend Testing

Bend testing determines the ductility or the strength of a material by bending the material over a given radius. Following the bend test, the sample is inspected for cracks on the outer surface. Bend Tests give analysis on:

- Ductile or Strength of a Material

- Modulus of Elasticity

Bend Testing is performed per:

- ASTM A370 – Standard Test Methods and Definitions for Mechanical Testing of Steel Products

- ASTM E290 – Standard Test Methods for Bend Testing of Material for Ductility

Rockwell Hardness

Rockwell Hardness Testing is hardness test based on an indentation hardness of a material. The Rockwell test determines the hardness by measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload. Stegman Inspection Services performs Rockwell testing under these forces:

- Rockwell Testing Is Done Under 100kgf and 150kgf Loads

- Superficial Testing Is Done Under 15kgf, 30kgf, and 45kgf Loads

Rockwell Testing is performed per:

- ASTM E18 Rockwell Hardness Testing of Metallic Materials

In-House Machine Shop

Our In-House machine shop can process your material into specimens conforming to all your requirements. Our services include:

- CNC Milling

- CNC Turning

- Wire EDM

- Laser Cutting