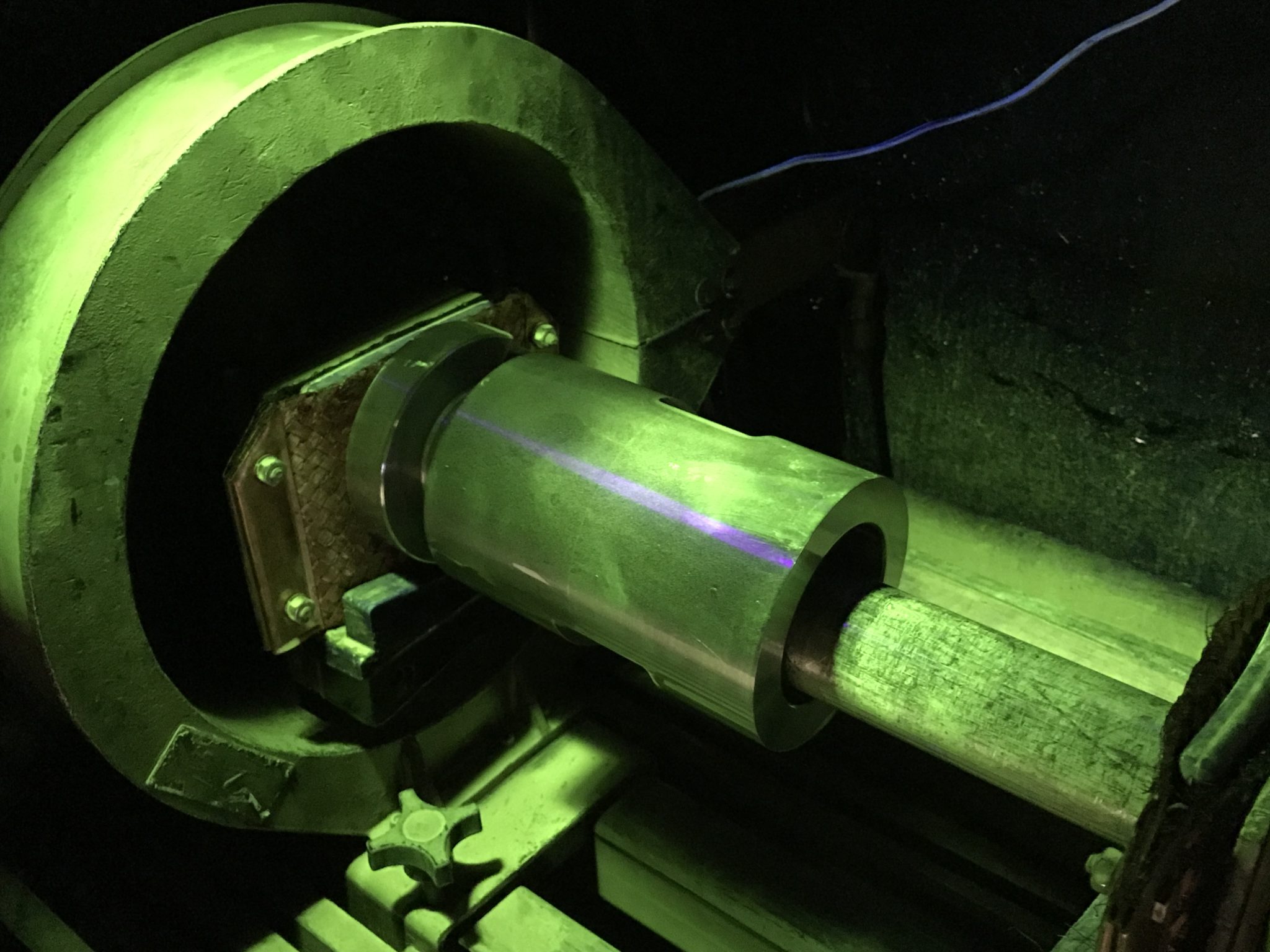

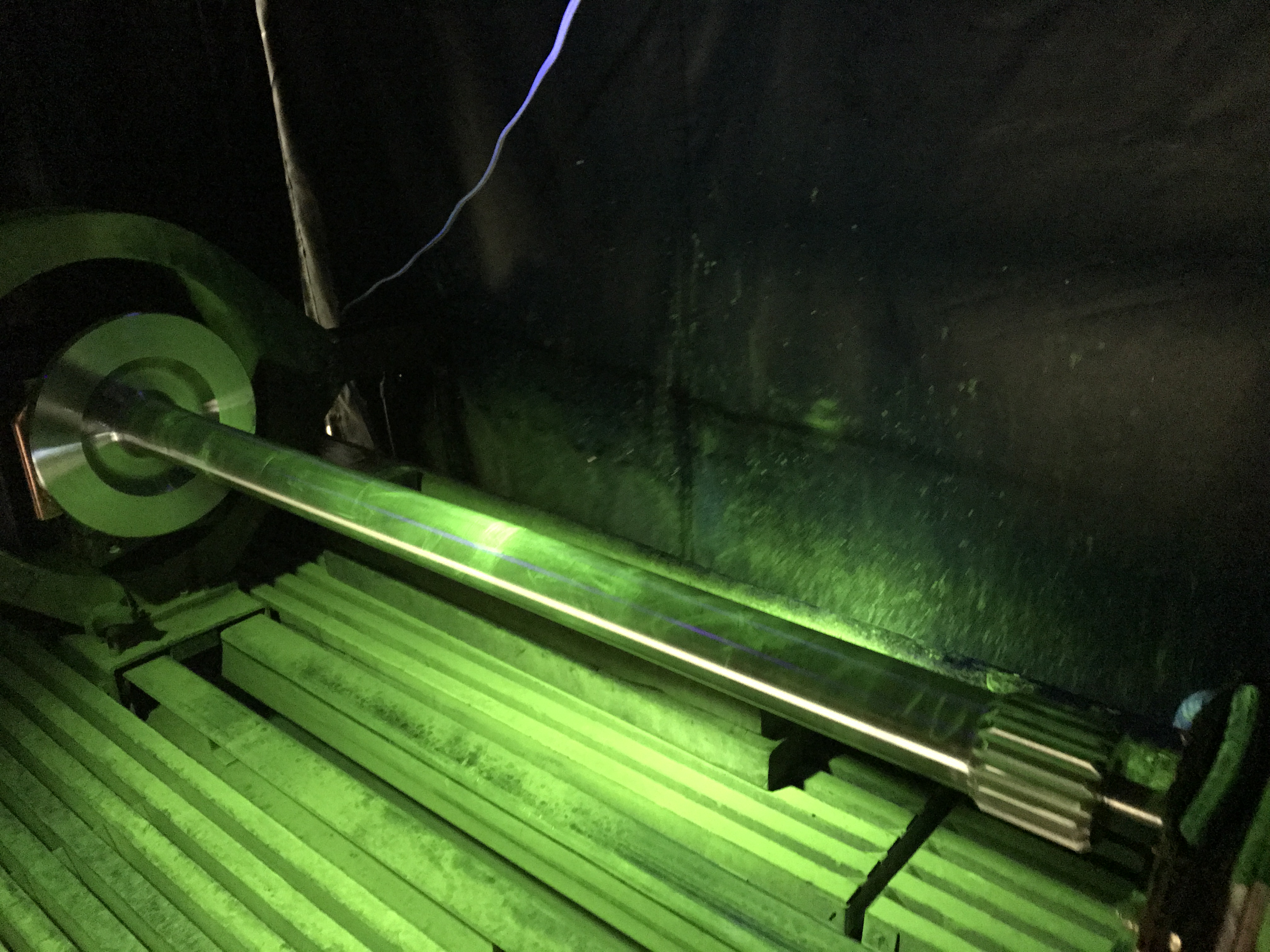

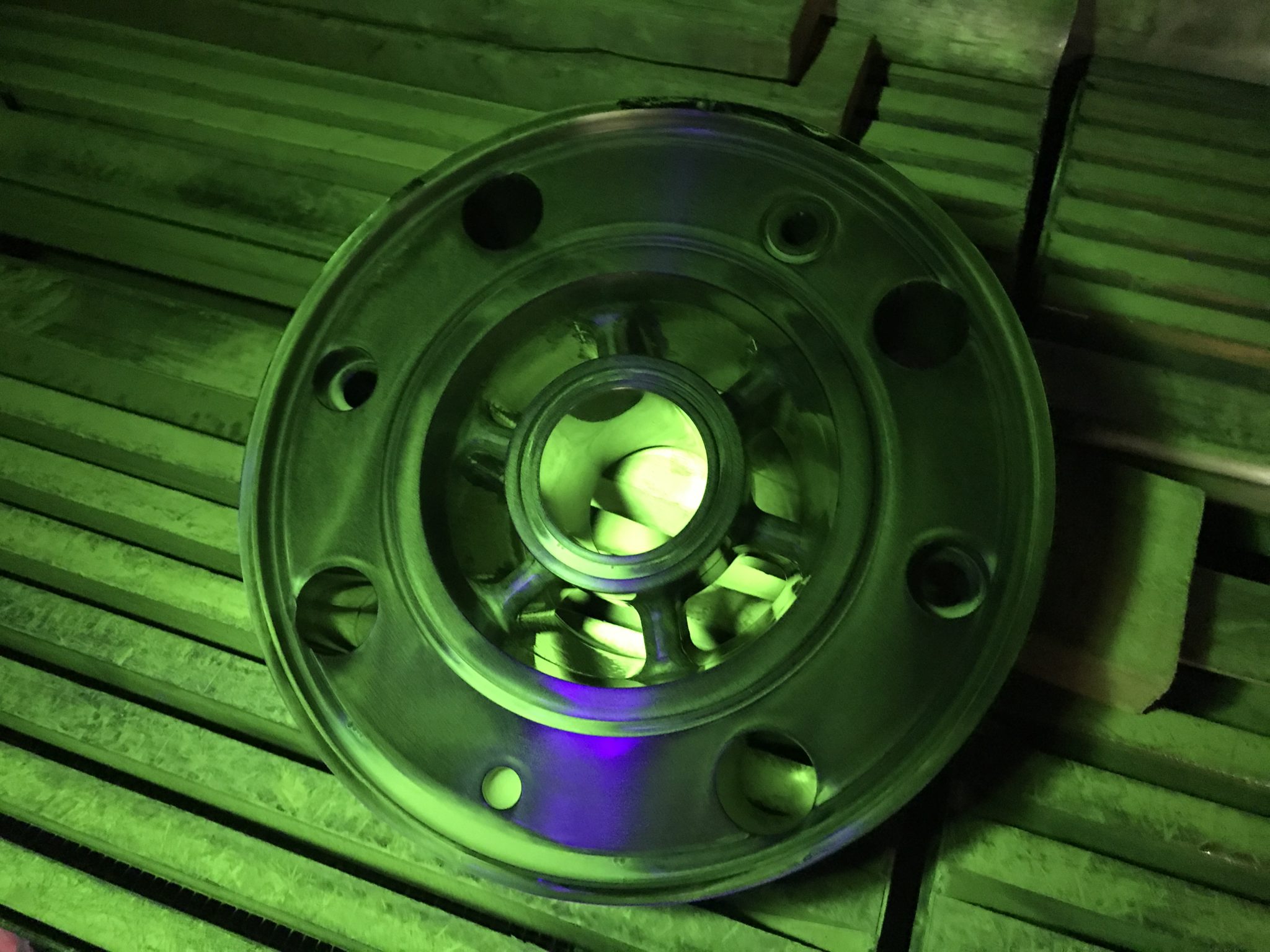

Magnetic Particle Inspection (MT) electrically induces magnetic fields in ferrous material to create a highly sensitive inspection method. This method can detect miniscule cracks and slightly subsurface discontinuities that can lead to part fatigue and eventually part failure.

Stegman Inspection Services performs this fast and reliable inspection method on castings, forgings, weldments, automotive parts, fasteners, and other part critical components. To assure compliance and conformance to customer specification requirements we offer:

- Level 2 and ASNT Level 3 Inspectors to evaluate the examination results

- Visible Dry and Wet Fluorescent MPI methods

- Emailed Certified Test Reports with your requirement and/or your metallurgical trace data documented with each order

With Stegman’s Inspection Services wet fluorescent magnetic particle inspection you are choosing a more reliable test with:

- Highly visible fluorescent indications in darkened environment

- Detection of fine surface cracks are more easily distinguished

- Oil/water based carrier for a more even application on the part

- On site ASNT Level 3 Consultation Available

Test Methods & Specifications

- ASTM E1444-16 – Standard Practice for Magnetic Particle Testing

- ASTM E709-15 – Standard Guide for Magnetic Particle Testing

- ASTM A275-15 – Standard Practice for Magnetic Particle Examination of Steel Forgings

- MIL-STD-1949A – Magnetic Particle Inspection

- General Electric P3C-AL-0003 – Magnetic Particle Inspection of Steam Turbine and Generator Components

- General Electric P3C-AL-0012 – Magnetic Particle Testing Acceptance Standard For Steam Turbine Stationary Components

- General Electric P3C-AL-0201 – Magnetic Particle Testing Acceptance Standard For Steam Turbine and Generator Studs, Bolts, and Nuts (Hardware)